yext

Gatherall Bindery, Inc.

Last time updated: 10/26/23, 6:04 PM

About

Gatherall Bindery (Established 1967) is Michigan’s largest trade-only bindery. We have 30+ team members and over 40,000 square feet to serve you. We are able to turn around many jobs in as little as 36 hours. We have the equipment, capacity, and capability to meet your deadlines with our entire team at your disposal. No matter how large or how small your order might be, we look forward for the opportunity to serve you.

Ensuring your books, magazines, and brand materials have the perfect binding to them is a task that we accomplish every time for each of our clients. We ensure the edges are trimmed evenly and the cover is fitted tightly to the pages.

Images

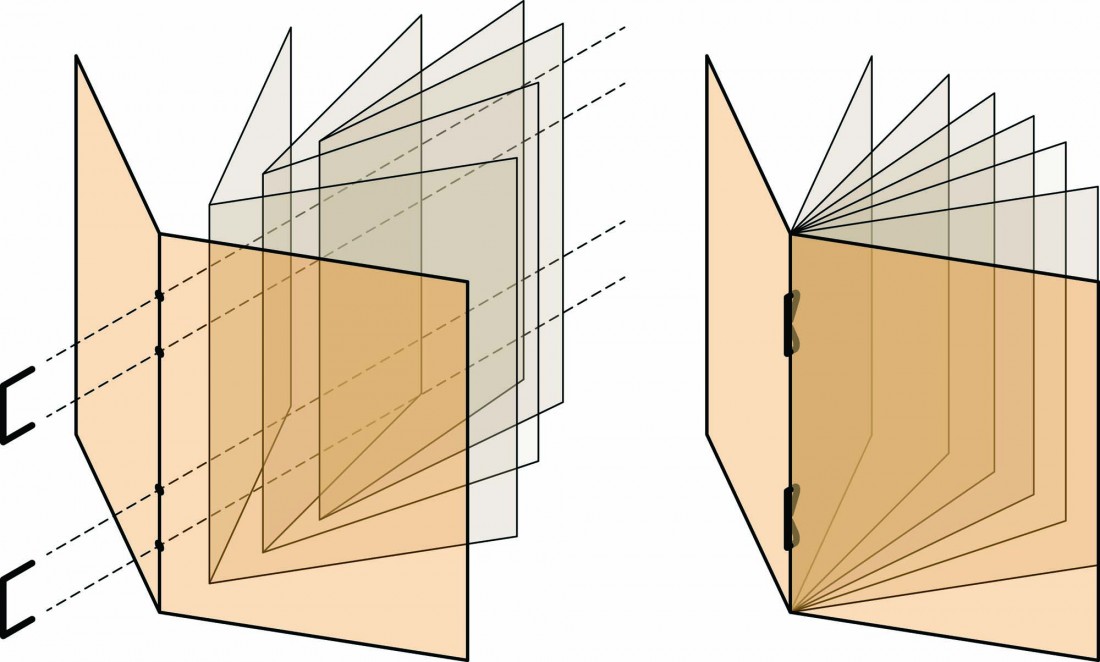

Saddle stitching is when pieces of paper are folded or nested together and held in place by a set of staples or something similar to ensure the product will not fall apart. More often than not, two staples are standard industry practice.

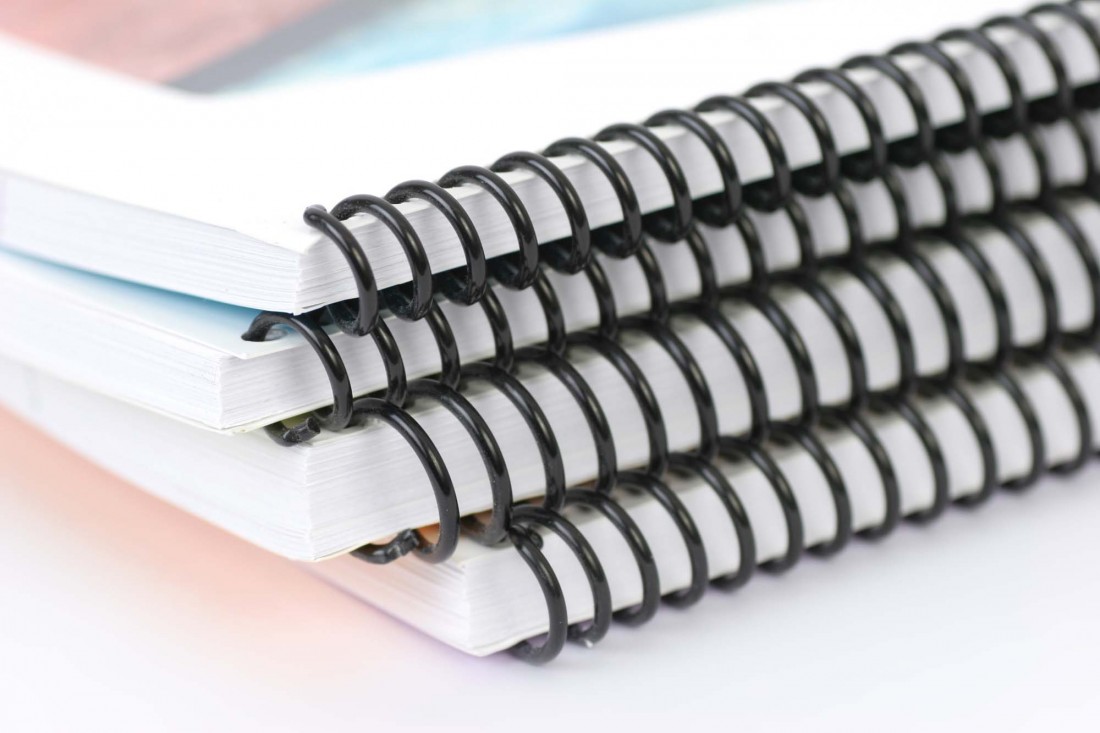

The biggest advantage of spiral binding compared to wire-o binding is that it is much more durable. Because they are bound with so many joints in the spiral, sheets are less likely to fall out or become damaged as a result of the binding. If you or your customer plan to refer to the product you are binding a lot, we recommend considering spiral binding so it holds up to routine wear and tear.

We can laminate either single or double-sided, with a flush cut or sealed edge. Lamination film is available in 1.7 mil (standard), 3 mil, 5 mil, and 10 mil thicknesses. Plus, you can choose from polypropylene (economy grade), polyester (standard), and nylon (mostly used for single-sided applications) film. Most of today’s short-run color documents are printed on toner-based digital presses or color copiers –our hi-tack (lower temperature) film is perfect for these projects.

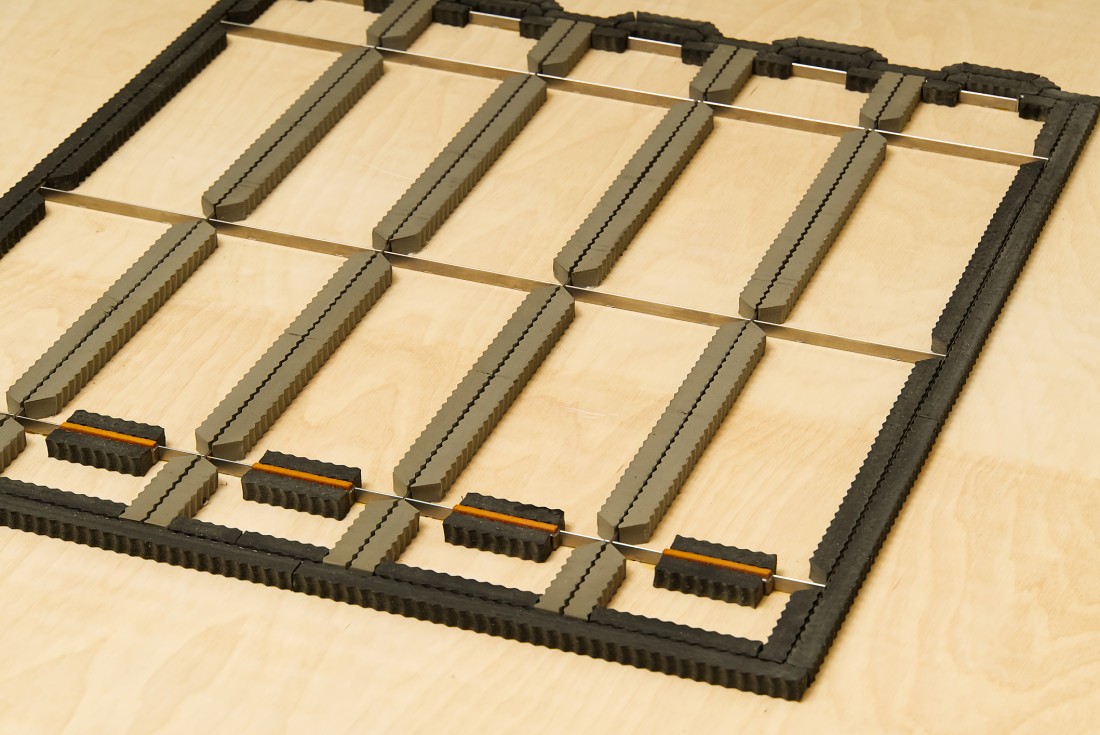

If you are unsure of what you want your finalized product to look like, or you are interested in having a product die-made, our team of engineers will help you develop a CAD rendering of your product. We have worked with companies across Michigan and into the Midwest USA to create packaging for their products.

Perfect binding uses PUR or EVA glue to keep your pages and the cover bonded together. The primary difference between the two is that PUR glue is an adhesive that reacts with the fibers of the pages it’s binding during the curing process. In most cases, either EVA or PUR glue would be an excellent choice for your perfect binding needs.

Our systems will keep track of all your customer’s information, so when it comes time to begin the mailing and fulfillment process, it can be done efficiently. With high-speed UV inkjetting, we can print a recipient's address on the envelope or package we are mailing.

Frequently Asked Questions

When was Gatherall Bindery, Inc. founded?

Gatherall Bindery, Inc. was founded in 1968.

Which days is Gatherall Bindery, Inc. open?

Open on Monday, Tuesday, Wednesday, Thursday, Friday.

What are Gatherall Bindery, Inc. main services?

Binding, Perfect Binding, Saddle Stitching, Mechanical Binding, Print Finishing, Mailing & Fulfillment, Die Cutting, Fold & Glue.

Attention business owner!

Register your business now and enhance your global reach with iGlobal.

Copied to clipboard!